|

|

|

|

| |

About Our

System

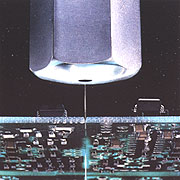

This advanced cutting system derives its efficiency and power by

pressurizing water at up to 55,000 psi... and focusing it through a jewel as

small as .003" in diameter. Traveling at speeds up to 3 times the speed of

sound, the jetstream cuts without heat and exerts little vertical or lateral

force. This advanced cutting system derives its efficiency and power by

pressurizing water at up to 55,000 psi... and focusing it through a jewel as

small as .003" in diameter. Traveling at speeds up to 3 times the speed of

sound, the jetstream cuts without heat and exerts little vertical or lateral

force.

Abrasives can be introduced via the Paser System™...

Particle Stream Erosion. This abrasive jet cuts by impacting and eroding the

workpiece, rather than sawing, severing, shearing, burning or grinding, thereby

eliminating material degradation.

The waterjet cuts relatively soft

material with ease. With the Paser™, it cuts the hardest alloys and

composits faster and cleaner than lasers and conventional

methods. |

| |

|

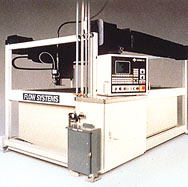

Computer

Controlled |

|

Close loop DC servo motors drive the

fully programmable, 3-axis gantry with submicron positioning accuracy. These

motors provide flexible, quick-response positioning, accuracy to within .001"

for shape or contour cutting-depending on material type and thickness. The

water knife path is controlled by computer and with its 3-axis capability, it

can cut complex shapes and contours effortlessly. Close loop DC servo motors drive the

fully programmable, 3-axis gantry with submicron positioning accuracy. These

motors provide flexible, quick-response positioning, accuracy to within .001"

for shape or contour cutting-depending on material type and thickness. The

water knife path is controlled by computer and with its 3-axis capability, it

can cut complex shapes and contours effortlessly.

The small kerf, speed

and precision of our cutting system makes it ideal for cutting sensitive

materials. Equally important, the low cutting temperature and the fact that

there are no clamps, drills or other tool contact with the material assures

there will be no substrate damage.

|

|

|

Home | About Our System |

Cutting Capabilities |

Materials Cut |

E-mail

431 Water Street

· Wakefield, MA 01880-2597

Tel:

800.334.4781 or 781.245.0573 · Fax:

781.245.1636

|